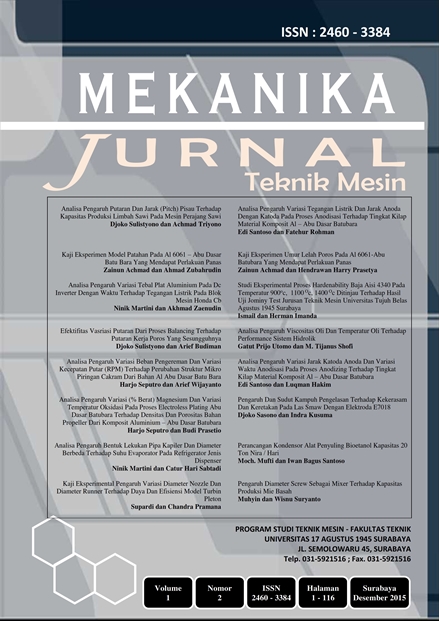

ANALISA PENGARUH VARIASI TEGANGAN LISTRIK DAN JARAK ANODA DENGAN KATODA PADA PROSES ANODISASI TERHADAP TINGKAT KILAP MATERIAL KOMPOSIT AL – ABU DASAR BATUBARA

Abstract

Composites have been developed in the world of manufacturing especially Metal Matrix Composites (

MMCs ). It is light resistant to corrosion, and mechanical properties has been successfully repaired in various

studies, make this material superior in terms of durability. But the appearance need to be improved to obtain a high

decorative value through anodizing process. Coloration process using this anodizing method has been used for

coloring aluminum metal. Anodizing process carried out by the independent variable electrical voltage between 8,

10, and 12 Volt and anode cathode distance 0.10, 0.15, and 0.20 m with 10 minutes of processing time. Coloration

results are tested using test equipment gloss sheen Micro-Tri-Gloss with reflection angle of 85

. The results showed

that the variation of the electric voltage supplied to the anodizing process proved to be able to give much influence

on the vulnerable 8 , 10 , and 12 Volt. Material reflectance values tend to decrease. This happens because the

higher the voltage , the greater the material pore. The same is shown on the chart the influence of sulfuric acid

concentration and the voltage of the pore diameter. In the graph shows an increase continuously - as you constantly

given electrical voltage. Anode cathode distance variation on the anodizing process also proved sufficient to provide

a significant influence on susceptible 0.10 , 0.15 , and 0.20 m. Material reflectance value tends to increase with the

addition of anode cathode spacing. Such things happen because of the obstacles posed increasingly stable , the

formation of smaller pore structure and equitable causes deposition of dye attached to the surface of the object is

flat and the color quality is increasing. The highest reflectance values obtained at a voltage of 8 volts of electricity

with the anode cathode spacing 0.15 m. While the lowest reflectance values obtained at a voltage of 10 volts of

electricity with the anode cathode spacing 0.10 m.

Keywords : anodizing , voltage, anode cathode spacing , reflectance

Downloads

References

Galuh, P. (2007). Retrieved from http://www.putragaluh.web.id/: http://www.putragaluh.web.id/post/read/74/Ganesha_Digital_Library_4.2.html

Kemdikbud, P. (n.d.). https://perpustakaan.kemdikbud.go.id. Retrieved from https://perpustakaan.kemdikbud.go.id: https://perpustakaan.kemdikbud.go.id/perpus/?page_id=224

Shahkar Tramboo, H. S. (2012). A Study on the Open Source Digital Library Software’s. International Journal of Computer Applications, 1-9.

Verma, N. K. (n.d.). Institutional repository software and their use by the national institutes of. National Seminare "Role Libraries in Hingher Education : Problem and Prospects" (pp. 1-8). Mizoram: Goverment Aizawl Noth College.

webometrics. (2016). Retrieved from http://repositories.webometrics.info/en/Asia/Indonesia

pada aluminium terhadap kecerahan dan

ketebalan lapisan. Jurnal Teknik Mesin

Universitas Udayana ; 2010. hlm 75 – 82.

ï‚· Yoriya, Sorachon. Effect of inter-electrode

spacing on electrolyte properties and

morphologies of anodic tio

nanotube array

films. National Metal and Materials Technology

Center ; 2012. hlm 9454 – 9464.

ï‚· Fauzia, Salma. Proses Anodizing dan

Elektroplating. 2014. Laboratorium Teknik

Mesin Politeknik Negeri Jakarta.

ï‚· Sidharta, Bambang Wahyu. Pengaruh

konsentrasi elektrolit dan waktu anodisasi

terhadap ketahanan aus, kekerasan, serta

ketebalan lapisan oksida paduan aluminium

pada material piston. Jurusan Teknik Mesin,

Institut Sains & Teknologi AKPRIND ; 2014.

hlm 10 – 21.

Published

Issue

Section

License

Mekanika : Jurnal Teknik Mesin allows readers to read, download, copy, distribute, print, search, or link to the full texts of its articles and allow readers to use them for any other lawful purpose. The journal allows the author(s) to hold the copyright without restrictions. Finally, the journal allows the author(s) to retain publishing rights without restrictions